AmPro Powder Handling Suite

Designed for AmPro Innovations 2018 - 2022 - https://www.amproinnovations.com/powder-handling

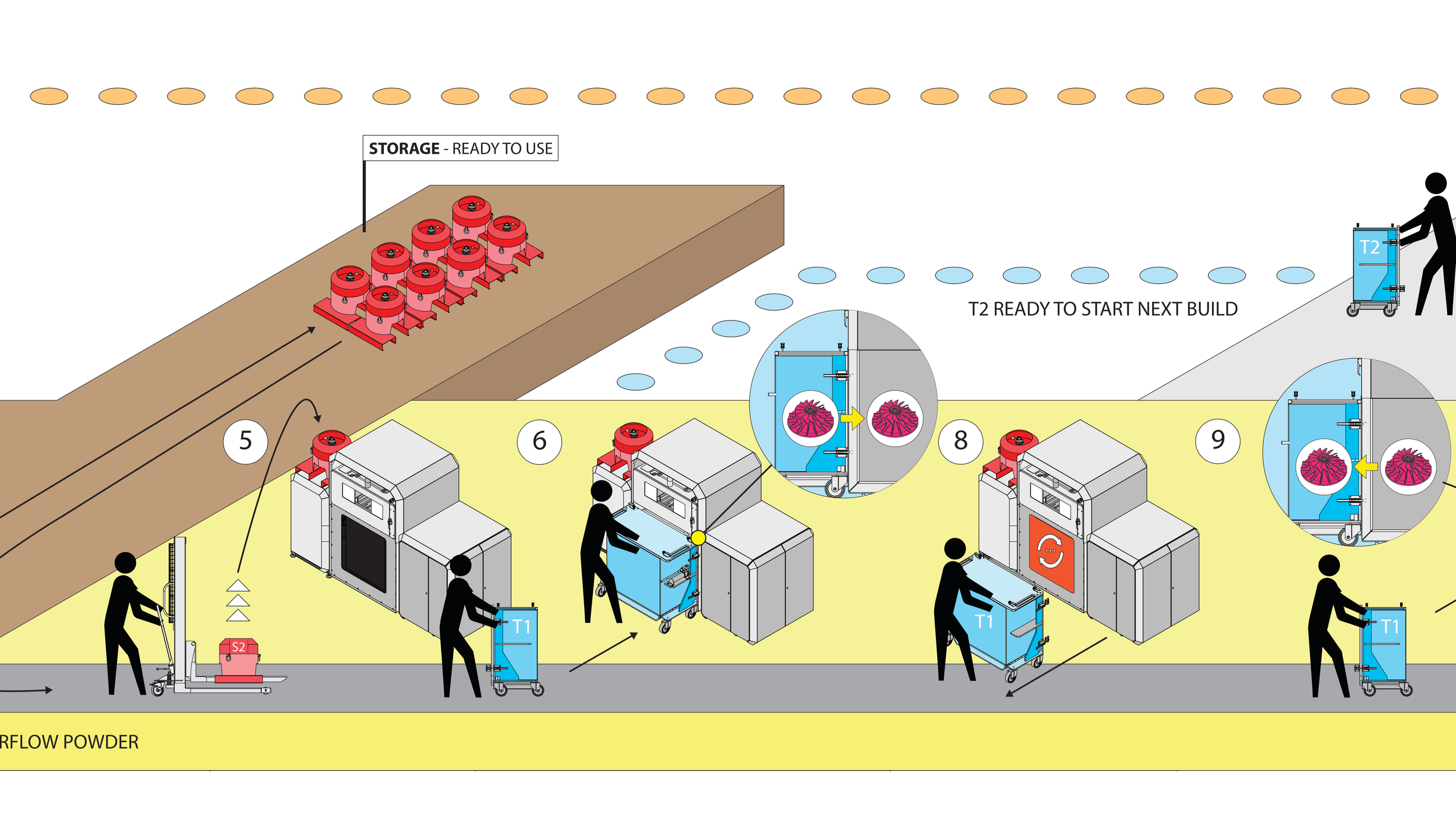

The brief for this project was to develop a fully closed-system powder handling suite for the metal 3D printing industry. Each unit is designed to seamlessly integrate, ensuring 0% open air exposure from raw powder all the way to finished part. Units are compatible with most industry standard additive manufacturing systems.

The final design outcome (from left to right): G4 Glovebox, DU40 Powder Decanter, PS Powder Silos, SU40 Powder Sieve, VU40 Vacuum Conveyor

Understanding powder flow through the system.

To better define the problem, and to easily convey the concept to investors, I developed a series of powder flow maps. These illustrate the way powder would move through each station of the system, how powder silos would integrate with printers and how powder would re-integrate back into the cycle.

Machine concept development

I developed the physical design of these machines for this project. The machines needed to be easy to make, visually appealing and of course meet a certain price point to be competitive.

My material choices were informed by how the machines would be made. An Australian team were to manufacture the initial units, with the full production to move to China. Sheet metal and welded RHS frames require no special tooling and can be recreated wherever the final manufacturing facility would be located.

AmPro Silos

The silos act as both storage and transport vessels for the metal powder for 3D printing. Our design utilized the strength of spun stainless steel and incorporated forklift and gantry lifting points, large top openings for powder inspection and easy cleaning, good operator access to inlet and outlet and pallet rack compatibility.

AmPro Powder Handling Suite

The AmPro powder Handling suite addresses many problems to make the 3D printing process more efficient and user friendly. The decanter has front access for silo installation and rear access for powder bottle access. The sieve allows for gravity fed powder sieving in small spaces. The vacuum conveyor houses all vacuum accessories onboard and users can maneuverer the machine around a facility on castor wheels.

Functional Prototypes

Our small team of designers and engineers had the unique opportunity of personally manufacturing the machines we designed. I was responsible for the manufacturing of the initial Decanter, Vacuum Conveyor and Sieve units for customer orders. I was hands on for all units that were produced by the Australian team, overseeing the frame and panel manufacture and the assembly process.